Marc Isambard Brunel (1769-1849).

Zeichnungen und Notizen von den Arbeiten an dem Gange unter der Themse von Rotherhithe nach Wapping. London: G. Schulze, 1828.

Our featured title for this month is a small guidebook in oblong format--9.5 x 13cm--describing the work-in-progress on the tunnel under the River Thames between Rotherhithe and Wapping (London). Engineered by Marc Isambard Brunel (1769-1849), construction on the tunnel began on 25 November 1825 and finished on 25 March 1843.

Several projects to build a tunnel under the Thames had previously been attempted in order to improve north-south communications. In 1798, Ralph Dodd suggested the construction of a tunnel between Gravesend and Tilbury. Although a shaft was effectively sunk at Gravesend in 1800-1802, construction was stopped for two main reasons: the presence of quicksand, which allowed the river to break in, and the exorbitant cost. In 1804, the Thames Archway Project was started for a tunnel between Rotherhithe and Limehouse. The engineer was Robert Vazie. After a shaft was sunk at Rotherhithe, Vazie began work on a drift-way. In November 1807, Richard Trevithik replaced Vazie as engineer. The drift-way eventually revealed that much of the strata was sand and gravel, giving way to quicksand occasionally. In 1808, a constant flood finally forced Trevithik to stop the excavation. The drift-way was only within 70 ft. of the north bank. In 1809, the Thames Archway Company opened a public competition for schemes that could effectively address the technical and financial challenges in the building of this tunnel. Charles Wyatt won with a proposal to make a tunnel by digging a trench in the bed of the Thames, sinking brick cylinders into the trench and joining them underwater. The Company hired John Isaac Hawkins to test the viability of the plan. In 1810-1811, the cylinders were built, lowered and joined with a mixture of mud and gravel. However, this new scheme again failed to solve the two familiar difficulties: the vulnerability of the riverbed and the high cost. As we will see in this essay, Brunel's engineering ingenuity eventually overcame both of these formidable challenges.

A royalist exile from revolutionary France, Brunel sailed to America in 1793. There he excelled as a civil engineer and architect, being in charge of ambitious projects such as the survey of a canal to link the Hudson River with Lake Champlain. For some time Brunel had been playing with the idea for the application of machinery to the manufacture of ship's blocks on a large scale--a ship block is a pulley or system of pulleys mounted in a case, used to increase the mechanical power of the ropes running through them (OED). After securing a letter of introduction to Earl Spencer of Althorp, first Lord of the Almiralty, Brunel decided to develop this scheme in England, where he arrived in 1799. The British government accepted his proposal in 1803. Three years later, 43 machines carrying out different processes in the manufacturing of blocks were functioning at Portsmouth Dockyard. The claim was that six men could now do the work it formerly took 60 men to do, saving £24,000 annually. Between 1805 and the early 1820s, Brunel was involved in numerous engineering enterprises, including experiments in steam navigation on the Thames, the design of bridges, docks, and a great variety of machines for wood-working, textile manufacture, printing, and sewing military boots.

In his Memoir of the Life of Sir Marc Isambard Brunel , one of the engineers working on Brunel's tunnel, Richard Beamish, offers us a detailed account of how Brunel first thought of how to overcome the technical difficulties encountered by previous engineers of the Thames tunnel. In 1816, R. F. Hawkins had secured himself a patent for a method in which he had absolute confidence. Two shafts of brick were to be sunk in the river two hundred feet from each shore. From these shafts, the excavations would proceed in both directions. The bottom of each shaft would form wells from which the water was to be removed by pumps located on the top of the shafts. This scheme aroused the attention of Brunel to the question of how to execute this project. In Beamish's words:

"At the time when Mr. Hawkins' project was put forward, Brunel was completing his works at Chatham, and one day, as he himself related to me, when passing through the dockyard, his attention was attracted to an old piece of ship timber which had been perforated by that well known destroyer of timber--the Teredo naualis . He examined the perforations, and subsequently the animal. He found it armed with a pair of strong shelly valves which envelops its anterior integuments, and that, with its foot as a fulcrum a rotary motion was given by powerful muscles to the valves, which, acting on the wood like an auger, penetrated gradually but surely, and that as the particles were removed, they were passed through a longitudinal fissure in the foot, which formed a canal to the mouth, and so were engorged. To imitate the action of this animal became Brunel's study.”

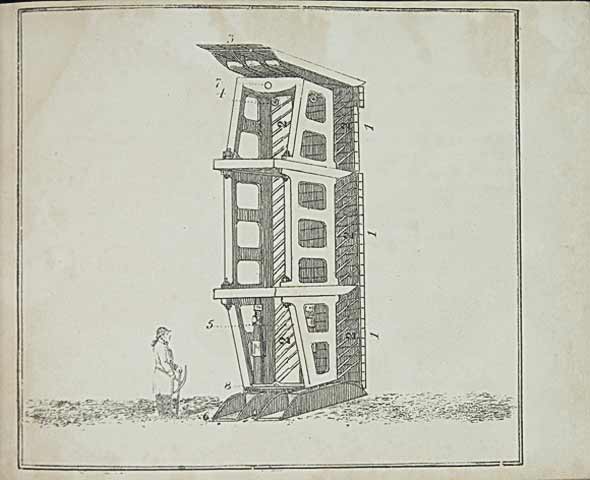

Inspired by the physiology of this curious mollusk, Brunel designed an innovative tunneling shield. It consisted of 12 frames, each standing side by side, and mounted on its own cast-iron ankle fixed to a large cast-iron foot. Each frame was divided into three cells, one on top of the other, each high enough for a man to stand in. The miners faced a wall composed of horizontal wooden planks, which held up the earth in front of them. Functioning as the poling that sheathes the galleries of mines, these poling boards were jammed tightly in place by heavy jack screws jutting outward from the edges of the frames, one at either end of each board.

Working in alternate frames, each miner removed one of his boards at a time, carved away a set number of inches of earth, then replaced the board and screwed up the jack, forcing it tightly into the new position. As soon as the poling boards of the three cells of a single frame had been advanced, the three miners in that frame eased off their poling board jack screws one at a time, and attached them to the edges of the idle frames on either side of them. Since the active frames were no longer holding up the face of the excavation, they could be forced forward safely. Immediately behind each miner, masons were bricking the recently formed walls, floor, and ceiling of the tunnel, leaving no area of the excavation exposed.

As regards the financial challenges, Brunel made a great effort to obtain necessary support by publishing articles promoting the project in numerous journals like theMechanic's Magazine , Museum , Register , and Journal & Gazette . This campaign attracted the interest of the Duke of Wellington, whose political influence was decisive in the creation of the Thames Tunnel Company. Indeed, the construction of the tunnel itself offered great economic advantages. Since watermen who ferried passengers between Rotherhithe and Wapping could not cope with the freight, it had to travel by land. Carts stacked with goods slowly moved through cobbled streets towards London Bridge, which was often traffic-clogged with wagoners from different parts of the city. The Thames tunnel, moreover, became a symbol of the increasing technological and political hegemony of Great Britain in the international scene.

The long-term construction of the Thames tunnel (1825-1843) generated a great amount of printed material, including articles in newspapers and scientific journals, guidebooks, broadsides, prints, and parliamentary reports. Much of this printing effort was designed to keep the interest of the public in the progress of the tunnel over the years. It also was a perfect way to raise money from visitors, who were first allowed to visit the works in March 1827. The first guidebook was issued in early 1827:Memoranda and views relating to the tunnel now excavating under the Thames, from Rotherhithe to Wapping . Afterwards, these guides appeared with great frequency, sometimes three or four times a year, including translations into the major European languages, such as our German version. Whereas Brunel wrote much of the text, draughtsmen and engineers working on the project designed the illustrations. We know the names of some of them: Pinchback (a draughtsman employed from March, 1824), Richard Beamish (hired as an engineer in 1826), and Brunel's son, Isambard Kingdom Brunel.

The numerous editions of these guidebooks--from 1827 through 1862--reflect the development of the project by introducing frequent changes of title, text, and plates. Our copy is particularly interesting because it is not recorded in the most comprehensive catalogue on this subject: The Triumphant Bore: A Celebration of Marc Brunel's Thames Tunnel (London: James Howden & Company, 1987). Additionally, while the title page is dated 1827, the preface (Einleitung) is dated 1828, and one of the plates, the view of the western archway of the tunnel, was first published in February 1828. Possibly the publisher of this German translation wished to emphasize the year when the tunnel was open to the public for the first time. Our copy includes 14 plates: five steel engravings (one of them folded), eight lithographs (three of them folded), and one aquatint on colored paper.

In the next part of this essay, we will include a brief description of each plate in the guidebook. These captions are based on Brunel's text itself, which clearly aimed to make technology accessible to the general public.

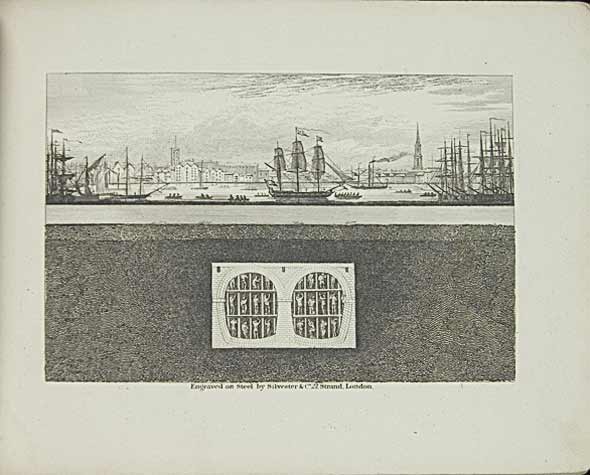

This steel engraving shows the transverse section of the shield with miners working in the frames and a view of Wapping with the churches of Shadwell and St. George's in the East.

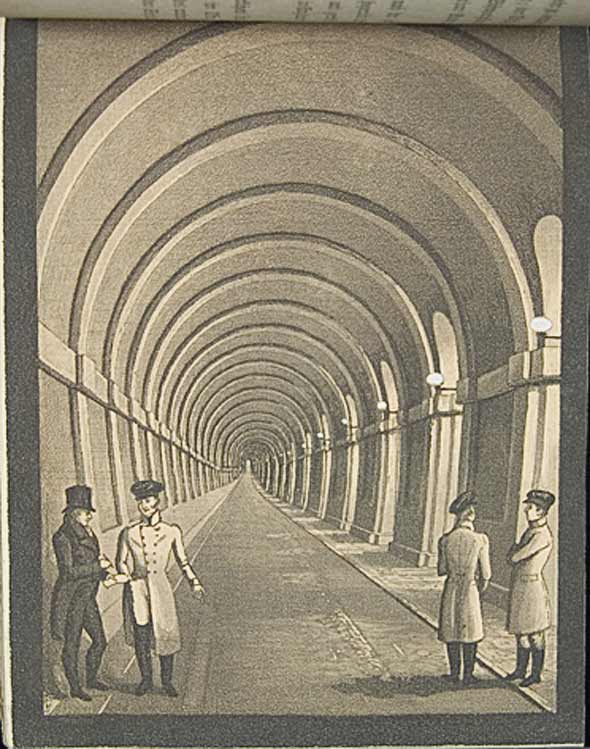

This aquatint on colored paper displays a view of the western archway of the tunnel, lighted by gas. Marc Brunel is standing on the extreme left. The three other men have been identified (left to right) as three engineers working with Brunel: Richard Beamish, Isambard Kingdom Brunel, and William Gravatt.

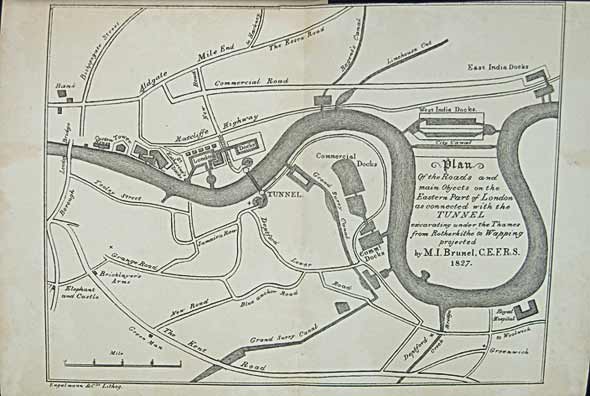

In this folding lithograph, we can see the plan showing the situation of the tunnel with regard to the following main roads and locations: London Bridge along Tooley Street, the Great Kent Road, Greenwich Church by Deptford Creek, Mile End Turnpike, and the Bank of England.

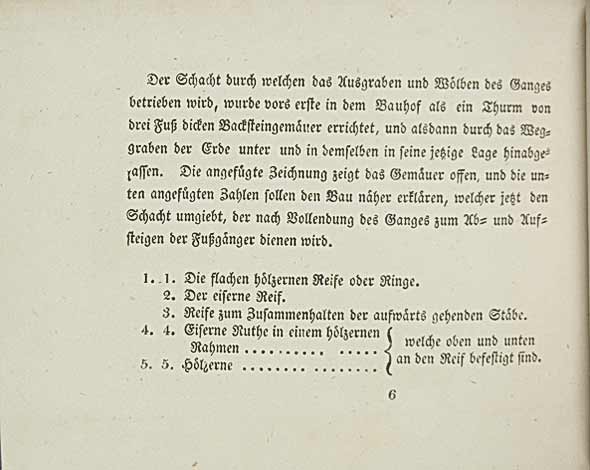

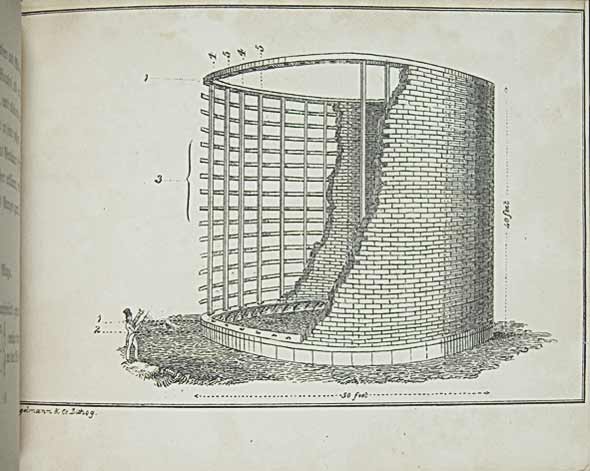

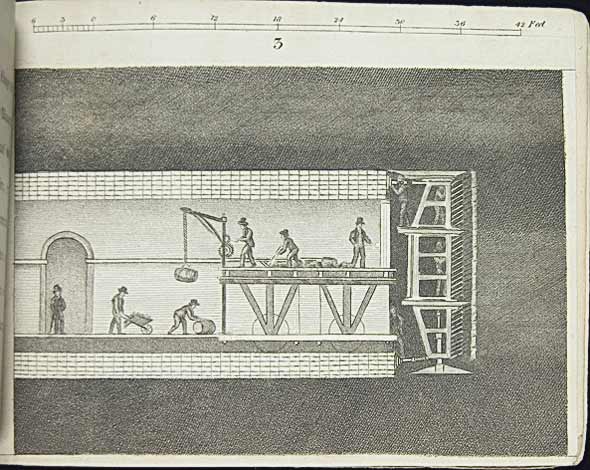

The shaft from which the excavation of the tunnel was carried was built originally as a tower made of brick, and then sunk into its position by digging the earth within. This lithographic sketch shows the interior structure of the shaft. The numbers referred by key in the opposite page describe the parts of this structure.

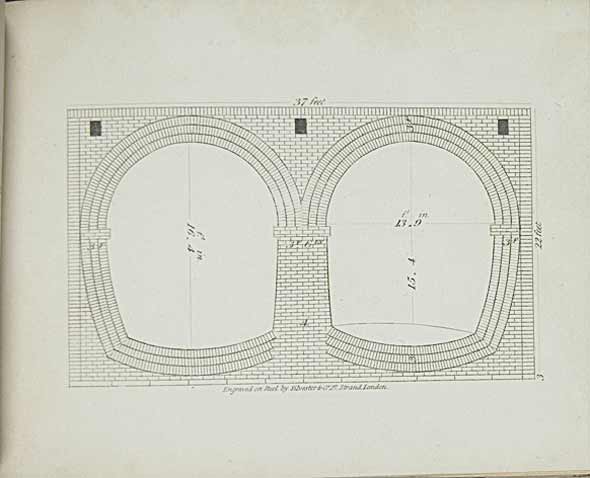

This steel engraving of the transverse view of the tunnel includes the dimensions of the brickwork: 37 ft. of width.

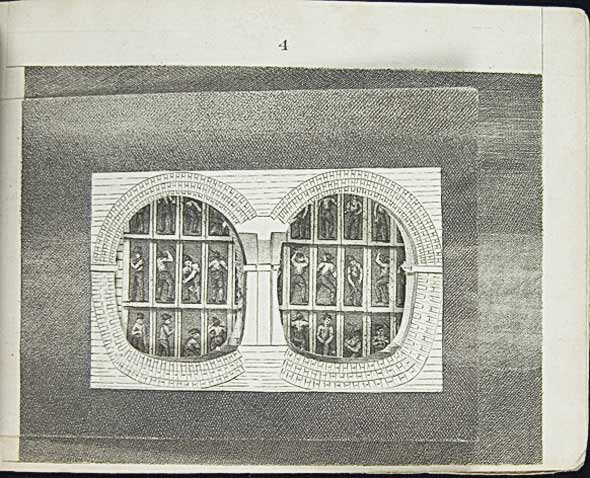

With an overlay of the tunnel, this lithograph displays a transverse view of the shield with men working in the cells of the frames.

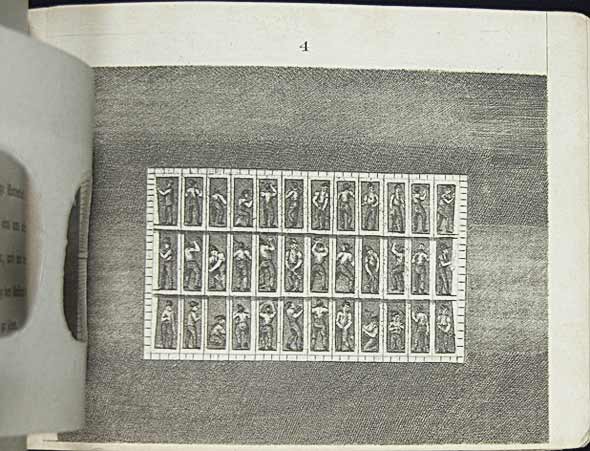

This lithograph illustration shows a longitudinal section of about 40 ft. of the tunnel, including a view of the one frame of the shield, the miners, and the brick workers. The horizontal screws on the head and foot of the shield are used to push forward the different divisions.

As a perfect illustration of the working of the shield, this lithograph displays the main parts of the structure: the poling boards, the jack screws, and the iron frame. In the opposite page, the key numbers describe the role of each part in advancing the shield.

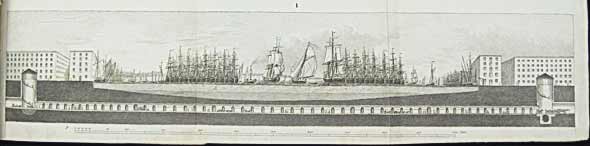

This folding lithograph shows a longitudinal view of the completed tunnel with the shafts at each end and a panorama of the river above.

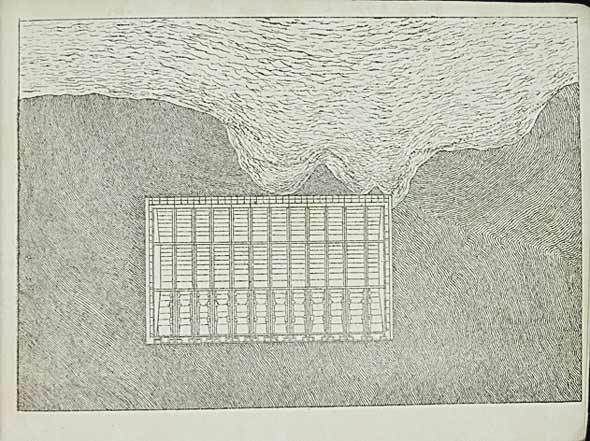

This engraving of the transverse section of the river shows the state of the riverbed following the accident of 18 th May 1827. The view of the shield shows the location where the loose materials and soil fell into the tunnel. The water completely filled the works.

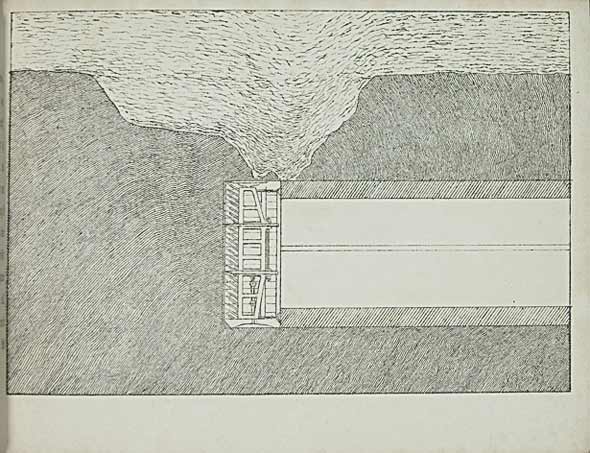

In this engraving we see a longitudinal outlook of the construction, including a side view of the shield with a section of the cavity created by the irruption of soil and water into the tunnel.

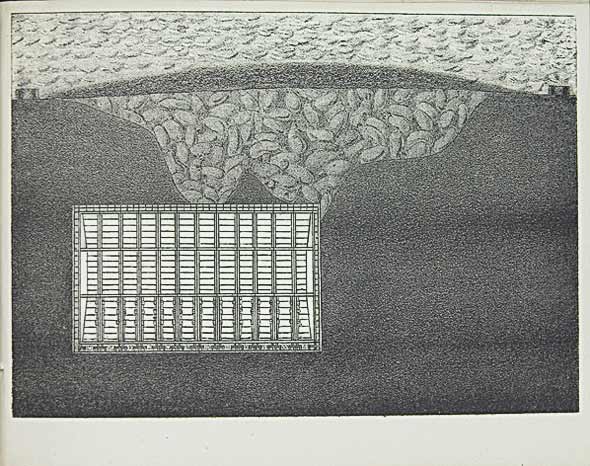

This lithograph displays a transverse view of the shield, showing how the large cavity has been filled up with bags of clay. These bags rest upon the iron shield, forming a new riverbed.

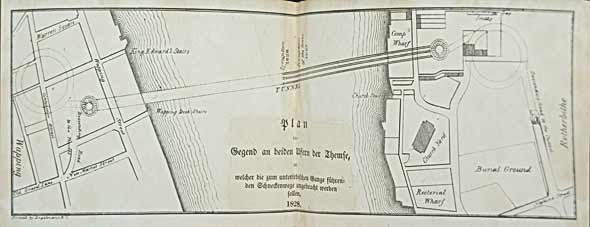

In this folding lithograph, we see a map of the progression of the tunnel, with a description of the premises at Rotherhithe and Wapping, where access to the tunnel will take place.

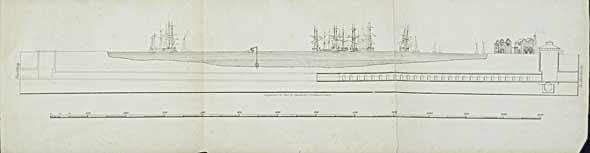

This folding engraving displays a longitudinal section of the tunnel, progress of work being 600 ft. from the shaft at Rotherhithe. The Rotherhithe shaft and buildings can be seen above.

The completed tunnel resembled the atmosphere of some of our modern underground stations. Aside from being a useful shortcut for both pedestrians and goods, the commercial potential of this new environment attracted a very diverse public, including merchants, expatriates, pickpockets, and some interesting tourists like Nathaniel Hawthorne. In his book of memoirs, Our Old Home: A Series of English Sketches, the American writer left us a vivid description of the tunnel after its completion:

"At present, it is illuminated at regular intervals by jets of gas, not very brilliantly, yet with lustre enough to show the damp plaster of the ceiling and walls, and the massive stone pavement, the crevices of which are oozy with moisture, not from the incumbent river, but from hidden springs in the earth's deepest heart. There are two parallel corridors, with a wall between, for the separate accommodation of the double throng of foot-passengers, equestrians, and vehicles of all kinds, which was expected to roll and reverberate continually through the Tunnel. Only one of them has ever been opened, and its echoes are but feebly awakened by infrequent footfalls.

Yet there seem to be people who spend their lives here, and who probably blink like owls, when, once or twice a year, perhaps, they happen to climb into the sunshine. All along the corridor, which I believe to be a mile in extent, we see stalls or shops in little alcoves, kept principally by women; they were of a ripe age, I was glad to observe, and certainly robbed England of none of its very moderate supply of feminine loveliness by their deeper than tomb-like internment. As you approach, (and they are so accustomed to the dusky gaslight that they read all your characteristics afar off,) they assail you with hungry entreaties to buy some of their merchandise, holding forth views of the Tunnel put up in cases of Derbyshire spar, with a magnifying-glass at one end to make the vista more effective. They offer you, besides, cheap jewelry, sunny topazes and resplendent emeralds for sixpence, and diamonds as big as the Koh-i-noor at a not much heavier cost, together with a multifarious trumpery which has died out of the upper world to reappear in this Tartarean bazaar."

This blog entry was originally contributed by Pablo Alvarez, Curator of Rare Books at the University of Rochester from 2003 to 2010.

Select Bibliography

Beamish, Richard. Memoir of the Life of Sir Marc Isambard Brunel. London: Longman, Green, Longman, and Brothers, 1862.

Chrimes, Michael M., Julia Elton, John May, and Timothy Millett. The Triumphant Bore: A Celebration of Marc Brunel's Thames Tunnel. London: James Howden & Company, 1987.

Clayton, Antony. Subterranean City: Beneath the Streets of London. London: Historical Publications Ltd, 2000.

Hawthorne, Nathaniel. Our Old Home: A Series of English Sketches. Boston: Ticknor and Fields, 1863.

Oxford Dictionary of National Biography: in Association with the British Academy: from the earliest times to the year 2000. 60 vols. Ed. H.C.G. Matthew and Brian Harrison. Oxford; New York: Oxford University Press, 2004.

Lampe, David. The Tunnel: The Story of the World's First Tunnel under a Navigable River Dug beneath the Thames 1824-42. London: George G. Harrap & Co. Ltd., 1963.